By Trisha Harinath

Acrylic, engineered stone, stone, glass, concrete and wood are just some of the materials that can now be used in the production of bathtubs, and with so much to choose from, it is strongly advisable for home owners to research products before purchasing them. According to Pierre Truter, from Tub and Spa Manufacturers, bathtub trends vary, however when clients are choosing tubs they need to pick the bath according to their required length and width, and should consider quality and rigidity as well.

Acrylic

According to Glenn Varrie, the marketing director of Summer Place Spas and Baths, one of the many reasons that his company chooseserpo to manufacture tubs in acrylic is that it is colour-fast and therefore does not fade or discolour. “Acrylic is also a very good insulator, ensuring that your bath water stays warmer for longer – it does not scratch easily and if scratches do appear on the tub, they can be buffed away with ease,” remarks Glenn.

He also adds that since acrylic is sturdy it is possible to make the product lighter, ensuring that the complete tub can be effortlessly and efficiently transported.

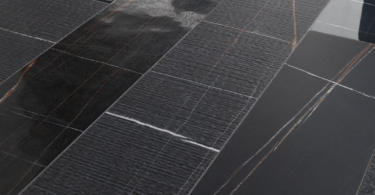

Engineered stone

Caesarstone is an engineered stone product made using resin and natural quartz. According to Afrigran, bathtubs made from caesarstone are durable, non-porous and stain-resistant. Due to its innate insulation properties, tubs made from Caesarstone are also warm to the touch.

Some of the other benefits that come from Caesarstone include its versatile design principles which ensure that clients are able to obtain custom-made bathtubs in accordance with their personal requirements and preferences, and with a variety of colours to choose from, consumers can purchase a bathtub which will complement the overall theme of their bathrooms.

Quarrycast

Quarrycast is made from finely ground volcanic limestone mixed with resin. As a stone-rich product, it is 100% one piece, hand finished and packed with naturally desirable properties. “The volcanic limestone in quarrycast means that every Victoria and Albert bath is naturally white and the special resin additives mean that with a light polish each bath also comes with a beautiful sheen,” says Alwyn Neethling, the sales director of Victoria and Albert Baths.

When it comes to customising quarrycast baths, Alwyn states that since the baths have a smooth exterior, they are easy to decorate using either oil or waterbased paints.

Quarrycast baths are also warm to the touch, strong, durable, renewable and have a beautiful finish.

Steel enamel

House of Style supplies an impressive range of steel enamel baths that are manufactured by Kaldewei. “Kaldewei manufactures tubs using 3,5mm thick steel enamel across its entire product range ensuring the stability, solidity and long life of its products,” says Andreas Lipinski of House of Style.

Andreas adds that steel enamel together with tile, ceramic and glass shower enclosures create a holistic look that conveys a feeling of harmony throughout any bathroom.

Some of the other benefits that Kaldewei baths offer include stability, robustness, scratch and abrasion-resistance, hygiene, ease of cleaning, colour-fastness and UV stability, as well as being recyclable as natural material.

Sygnite

Cast polyester quartz and polyester acrylic quartz composites, both known as sygnite, are also used to manufacture bathtubs. Sygnite is made up of about 70% crushed stone and therefore has a large component of natural materials in it. Clinton Johns, from Paradyne Bathware, says that cast polyester quartz makes the bath about 12mm to 18mm thick therefore allowing a good retention of heat when the bath water is poured in. He also adds that baths made from sygnite have a solid feel and guarantee longevity.

Apart from the above, there are quite a few different materials that are used in the manufacturing process of bathtubs. Mark van Kets, from Boutique Baths, advises home owners to ensure that they match features and benefits as well as weigh the pros and cons of different materials with their budgets as best as possible. “Understand what materials your bath is made from when committing to your purchase and do not overlook comfort for style. A bath must not only be attractive but must be a place for relaxation, therefore comfort surpasses all other issues – but get the balance right,” informs Mark. Dan Forsyth, from On Tap Somerset West/Stellenbosch, agrees to this and adds that the best way to test a bath is to actually lie in it.

“Home owners should also remember that depending on the application of the bath, a buyer must feel comfortable with the information that the salesperson has given him or her, as a bathtub is a fixture in the bathroom and can therefore not easily be changed once it is installed,” states Dan.

Finally, when choosing a bathtub, Kate van Niekerk, the marketing manager of Tile Africa, says that it is important for home owners to consider who will be using the bath as well. “Whether it is for children, the elderly, or adults, the bath at the end of the day needs to be practical for everyone using it,” concludes Kate.